About Us

Truck Oil Seals: Protecting Core Components, Facilitating Efficient Transportation - Full Range of Adaptation + Customization Services

Views : 2

Update time : 2025-07-14 15:38:00

In truck parts, although oil seals are small, they are "invisible guards" that ensure the normal operation of the vehicle. They are crucial to the stable operation of core components such as the power system and transmission system, and can effectively prevent lubricating oil leakage and block the intrusion of impurities.

1. What is an oil seal?

An oil seal, also known as a shaft seal, is mainly composed of a metal skeleton and a rubber sealing lip. Some special oil seals contain springs to enhance the sealing effect. It is specially used to seal the gap between the rotating shaft and the housing, such as the engine crankshaft, the input and output shafts of the gearbox and other parts. Its rubber lip is in close contact with the rotating shaft, which can prevent the leakage of internal lubricating oil and block the entry of external dust, sediment, moisture and other impurities.

2. What is the function of an oil seal?

The core functions of an oil seal are "oil sealing" and "protection". Through the close cooperation between the sealing lip and the shaft, it locks the lubricating oil inside components such as bearings and gears, preventing dry friction, overheating or even scrapping of components due to loss of lubricating oil. At the same time, it blocks the intrusion of external water, mud, sand and other pollutants, protects precision components such as shafts and bearings, and ensures the smooth operation of rotating parts.

3. How to choose an oil seal?

- Consider the working environment: For high-temperature environments (such as near the engine), choose fluororubber oil seals; For contact with hydraulic oil, diesel and other media, choose nitrile rubber with strong oil resistance; In dusty working conditions, oil seals with dust lips can be selected.

- Match the parameters of the sealing part: Select the appropriate specification according to the shaft diameter, groove size, etc., to ensure close fit after installation. At the same time, consider the rotation characteristics of the component to ensure that the oil seal can adapt to parameters such as the shaft speed.

- Combine with vehicle model and component requirements: Different vehicle models have different sealing requirements. For example, the transmission system of heavy trucks requires oil seals with better strength and wear resistance; For specific components such as gearboxes and hydraulic pumps, select the appropriate oil seal model according to their working pressure and speed.

4. What are the advantages of oil seals?

- Excellent material and reliable performance: Made of high-quality elastic materials, it has good wear resistance, temperature resistance, oil resistance and aging resistance. It can maintain stable sealing performance for a long time in the complex working environment of trucks (high temperature, high pressure, vibration, multi-media), reducing the frequency of replacement.

- Strong adaptability and wide application: There are various specifications and models, which can be adapted to trucks of different brands and models, including freight trucks, engineering dump trucks, special operation vehicles, etc. It can meet the needs of different rotating parts, and there are adapted products for shaft components from low-speed to high-speed rotation.

- Easy installation and low maintenance cost: The structure design is reasonable, the installation is simple, and no complex tools and technologies are needed. With good sealing effect, it can reduce component damage and maintenance costs caused by leakage, and reduce the overall operating cost of the truck.

- Ensure efficient operation of the vehicle: Through reliable sealing, it reduces lubricating oil leakage and component wear, reduces failure rates, improves vehicle attendance, and ensures the smooth completion of transportation tasks.

High-quality oil seals are key components to ensure the sealing performance of truck core components, reduce failures and lower costs. We provide a full range of oil seals adapted to different truck models, and can provide personalized customization services according to needs, with professional technical support and one-stop service, so that the truck sealing system can maintain the best state. If you have any needs, please feel free to consult!

相关新闻

Truck Oil Seals: Protecting Core Components, Facilitating Efficient Transportation - Full Range of Adaptation + Customization Services

Truck Oil Seals: Protecting Core Components, Facilitating Efficient Transportation - Full Range of Adaptation + Customization Services

Jul 14,2025

This article introduces the definition, functions, selection methods and advantages of truck oil seals, emphasizing their importance to the core components of trucks. We provide a full range of adapted oil seals, support personalized customization, and with professional services, to protect your truck.

Professional Truck Parts Supply: Full Range of Products and Customized Solutions to Escort You

Professional Truck Parts Supply: Full Range of Products and Customized Solutions to Escort You

Jul 14,2025

This article introduces a company specializing in truck parts. It has a full range of truck parts with complete models, suitable for various vehicle types, covering large parts such as axles and front hydraulic cylinders to small parts such as wheel hubs and cylinder gaskets. The company has a professional service team and engineers, capable of providing professional solutions and personalized customization services. It can create suitable products according to drawings, sizes or samples. Moreover, the products are of high quality and low price, dedicated to providing customers with cost-effective truck parts and support.

Truck Steering System: Core Guarantee for Control

Truck Steering System: Core Guarantee for Control

Jul 11,2025

This article introduces the truck steering system, which is the core of precise control. It consists of a steering control mechanism, a steering gear, and a steering transmission mechanism, and also includes a power assist system, with types such as mechanical hydraulic, electro-hydraulic, and electric power steering. It also mentions special technologies like rear-wheel steering and intelligent auxiliary steering, as well as maintenance points such as checking steering fluid and component connections, and looks forward to its future trends of electrification and intelligence.

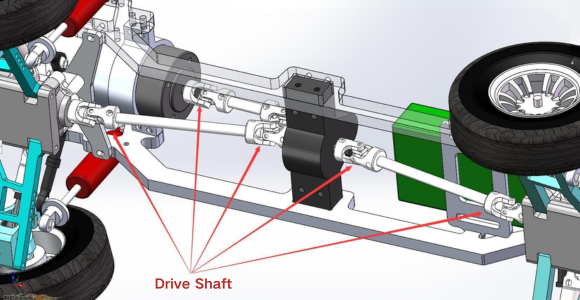

Truck Drive Shaft: The Key Link for Power Transmission

Truck Drive Shaft: The Key Link for Power Transmission

Jul 11,2025

This article briefly introduces the truck drive shaft, which is the core link for power transmission. It is composed of a shaft tube, a telescopic sleeve and a universal joint. It expounds its working principle of transmitting engine power to the drive axle through the gearbox, analyzes common faults such as looseness, bolt falling off and vehicle shaking as well as their causes, and also puts forward maintenance points such as regular lubrication, component inspection and reasonable driving, emphasizing that attention should be paid to its maintenance to ensure the operation of the truck.